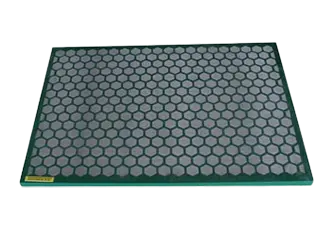

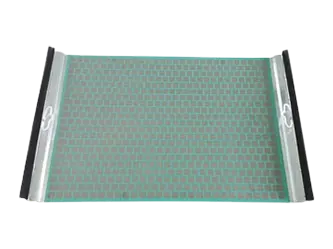

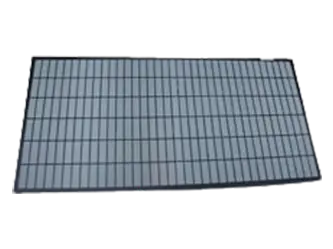

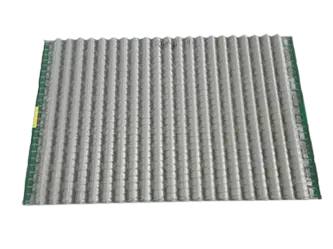

Shaker Screen is a mesh device used in drilling operations to filter out large solid particles from drilling fluids, improving efficiency and reducing equipment wear.

A Shale Screen is a crucial component of a shale shaker in drilling operations. It acts as a filter, separating solid drill cuttings from the drilling fluid. This filtration process allows the fluid to be reused, enhancing operational efficiency.

Shale Screens are designed to withstand harsh drilling conditions. They are typically made from high-quality, durable materials that can handle heavy loads and abrasive materials, ensuring long-lasting performance and reducing the need for frequent replacements.

Shale Screens come in various sizes and types to meet different drilling requirements. This customization allows for optimal performance in different drilling conditions, contributing to the overall effectiveness and cost-efficiency of drilling operations.

Shaker Screens are typically made from high-quality, durable materials to withstand the harsh conditions of drilling operations. The most common material used is stainless steel due to its strength, durability, and resistance to corrosion. Stainless steel screens are designed to handle heavy loads and abrasive materials, ensuring long-lasting performance. Some screens may also incorporate a layer of polyurethane or other synthetic materials for added durability and improved filtration capabilities. The frame of the screen is usually constructed from steel or composite materials for structural stability. The choice of material for a shaker screen depends on various factors, including the type of drilling operation, the nature of the drilling fluid, and the size and type of cuttings to be separated.

Email: benny@bzsolidscontrol.com

Email: benny@bzsolidscontrol.com

Call Us: 0316-5166559

Call Us: 0316-5166559

Address: Xiangfeng Street, Train Station Road, Sanhe, Hebei, China

Address: Xiangfeng Street, Train Station Road, Sanhe, Hebei, China